Kunshan Janbo Electromechanical Co., Ltd.

Fax: 0512-57711608

Contact: Mr. Cao

Mobile: +86 15950939002

Mobile phone: +86 15895657606

Postal Code: 215300

Website: www.janbo.biz

Address: No. 8, Nanhe Road, Development Zone, Kunshan City, Jiangsu Province

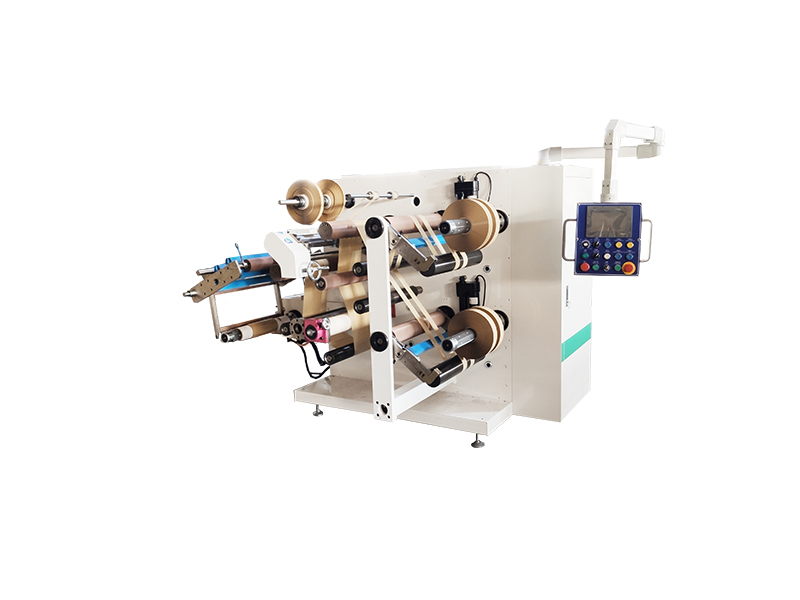

Function: All kinds of tape and other materials cut and rewind.

Specifications:

Maximum winding diameter: 800mm

Core diameter: 3-6"

Mechanical width: 0.3M-0.7M

Maximum feeding diameter: 800mm

Minimum slitting width: 50mm

Maximum mechanical speed: 200M/Min

Features:

1. Coiling power part: two coiling motors cooperate with the main motor to do three-motor continuous control, the main motor separates the feeding motor and the winding motor to control the tension, the tension of the finished product is stable, and the appearance is beautiful.

2. Winding machine part: The winding shaft adopts air expansion/slip system, which can automatically adjust the winding tension when winding, and the effect is better for materials with uneven thickness.

3. Motor control part: The operation interface adopts the LCD touch screen, which can directly set various winding conditions and operating conditions on the screen. The control part uses a programmable controller for mechanical action control, and has a self-testing system. When the machine fails, it can diagnose the fault cause by itself. 4. Cutting tool part: can choose the upper and lower round knife mechanism, air knife mechanism or industrial knife mechanism, easy to operate, can be suitable for a variety of materials.

5. Auxiliary press wheel device: The press wheel can be used after the material is rolled out, which can make the material more neat while driving the air.

6. Basic discharge form: combined discharge stand, short path, more convenient material.

Optional accessories

1. Auxiliary feeding of raw materials: The use of hydraulic power, suitable for the workshop without driving, can save manpower and shorten the loading and unloading time.

2. Ear material handling device: Optional independent or connected wire winding machine to pick up waste, in addition to strong windmill can be used for non-viscous materials.

3. Automatic line setting device: suitable for slitting after printing, which can be accurately aligned with the printing reference line for slitting.